This is in anticipation of part electrification of our process when a greater amount of renewable electricity is available from the grid.

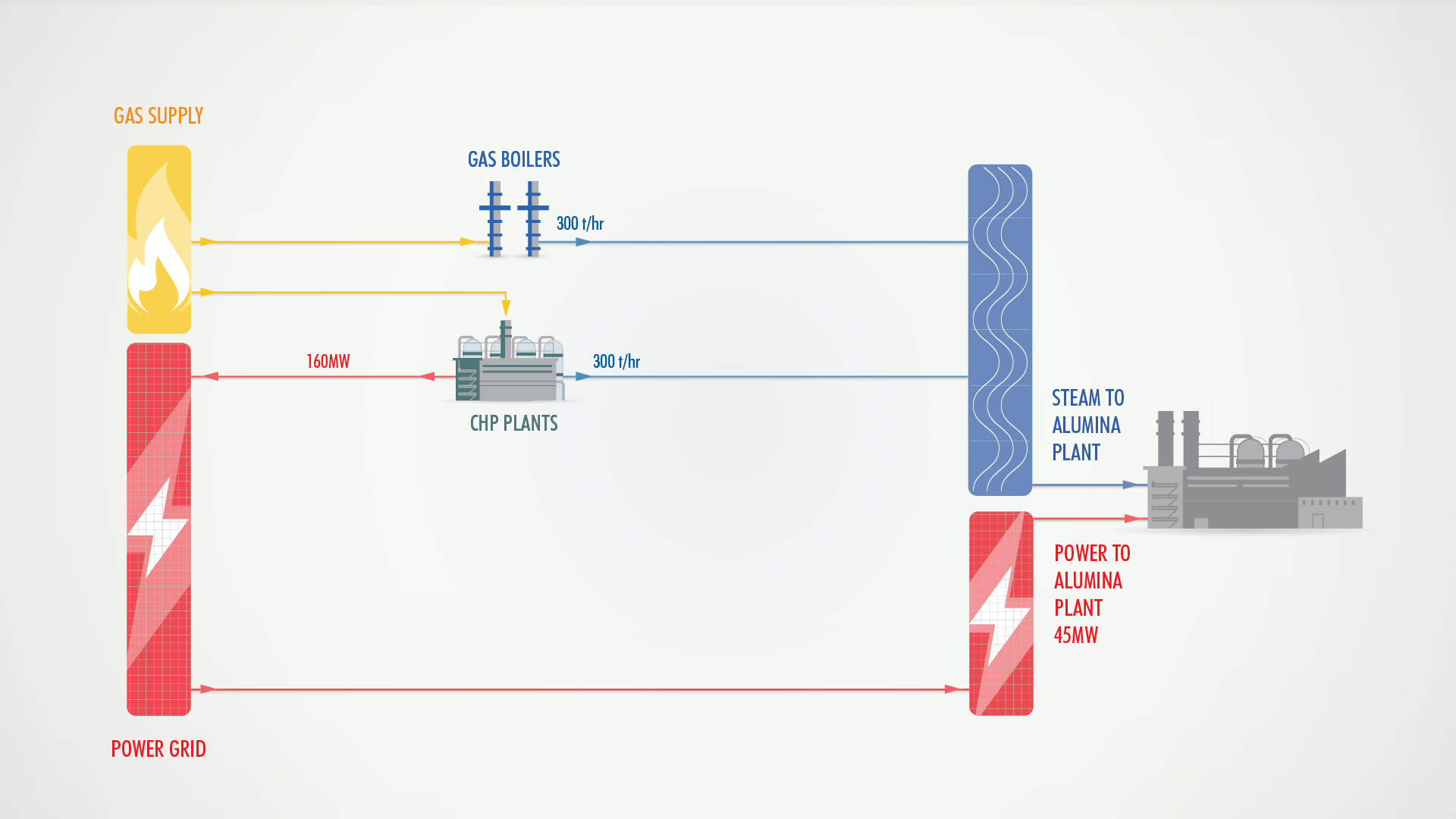

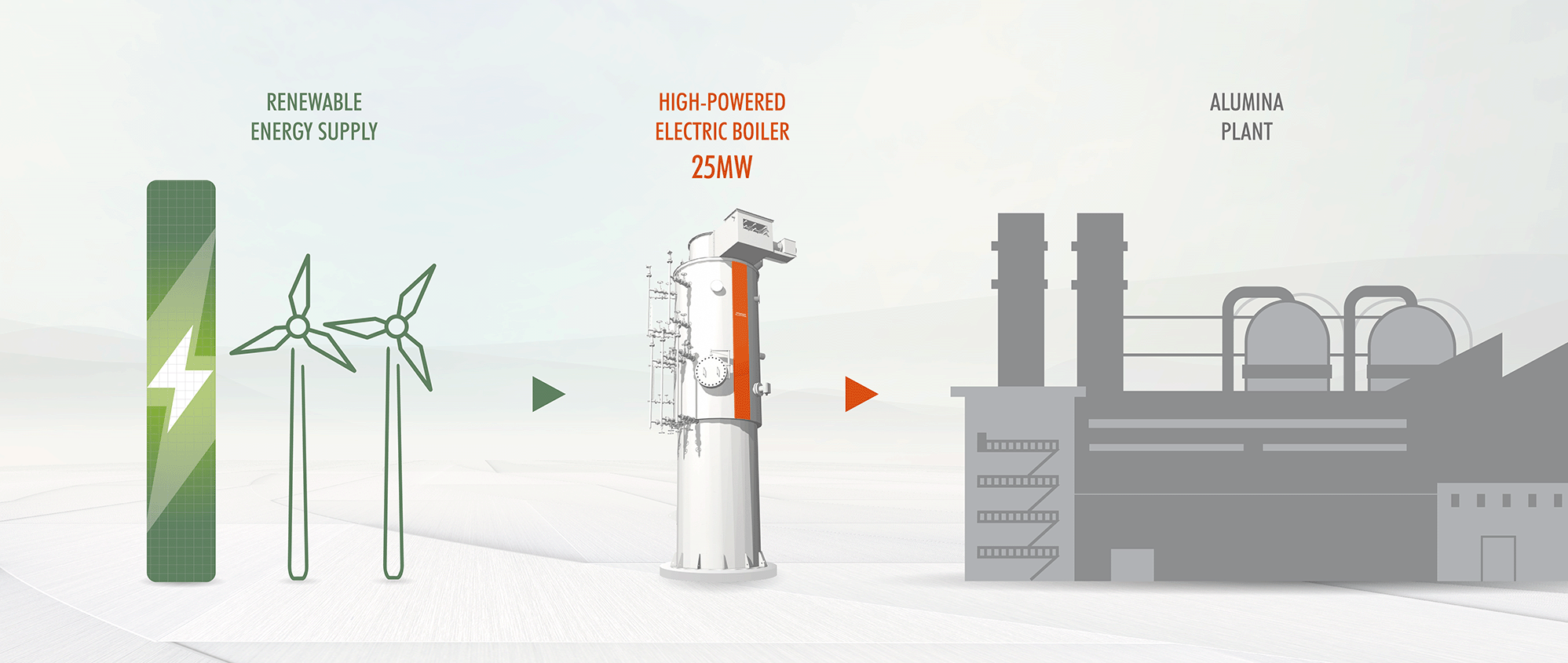

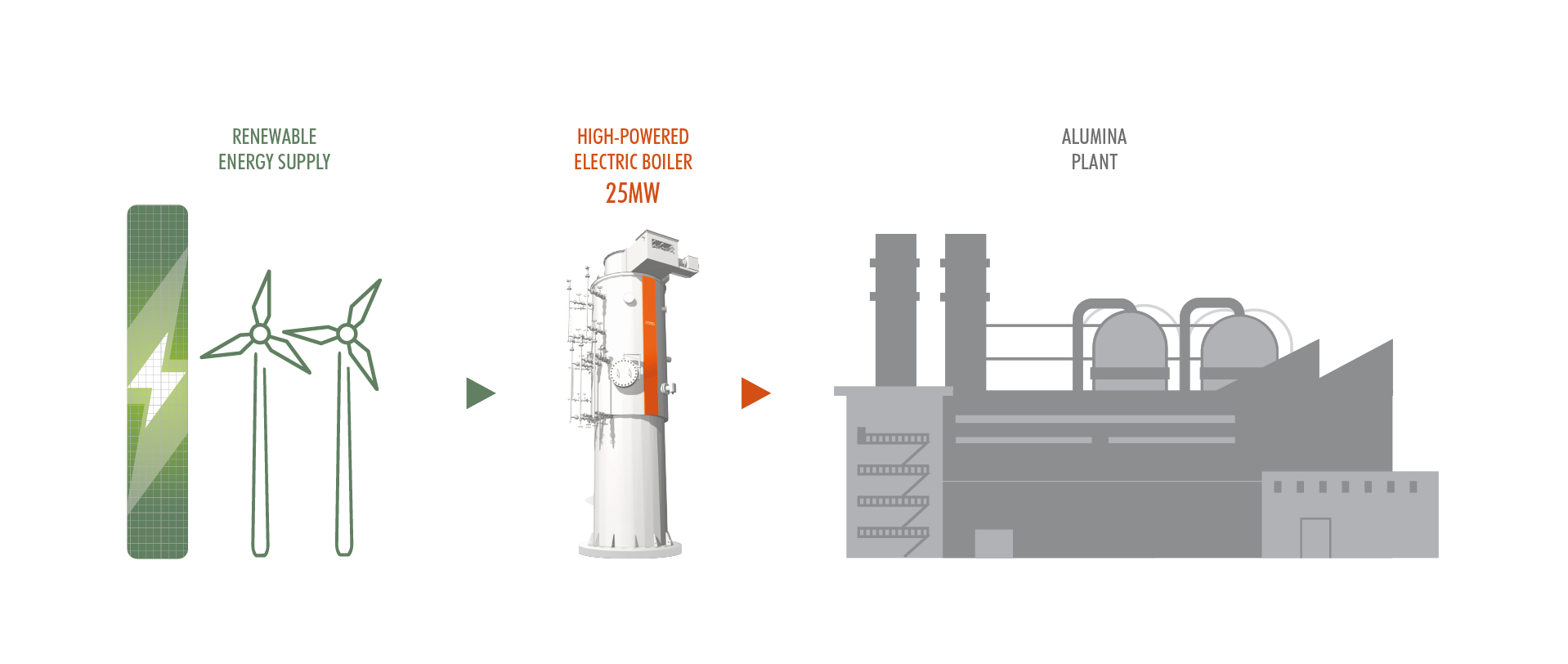

The high voltage, high-pressure electric boiler will take excess renewable energy from the grid and use it to generate high-pressure steam for the Alumina plant, displacing steam produced by the natural gas boilers.

The design and the pioneering installation of a 25MW High-Pressure Electric Boiler will be the first application of this type within the alumina industry. The high voltage, high-pressure electric boiler will take excess renewable energy from the grid and use it to generate high-pressure steam for the Alumina plant, displacing steam produced by the natural gas boilers. This is in anticipation of part electrification of our process when a greater amount of renewable electricity is available from the grid.

The electric boiler to be installed at Aughinish is a first-of-its-kind high-pressure boiler: Low-pressure electric boilers operating at up to 30 bar g have been in operation since the 1950s, this first-of-its-kind boiler will produce steam at 52.5 bar g and is rated at up to 62 bar g. This innovative high-pressure boiler has been developed between Parat and Equinor

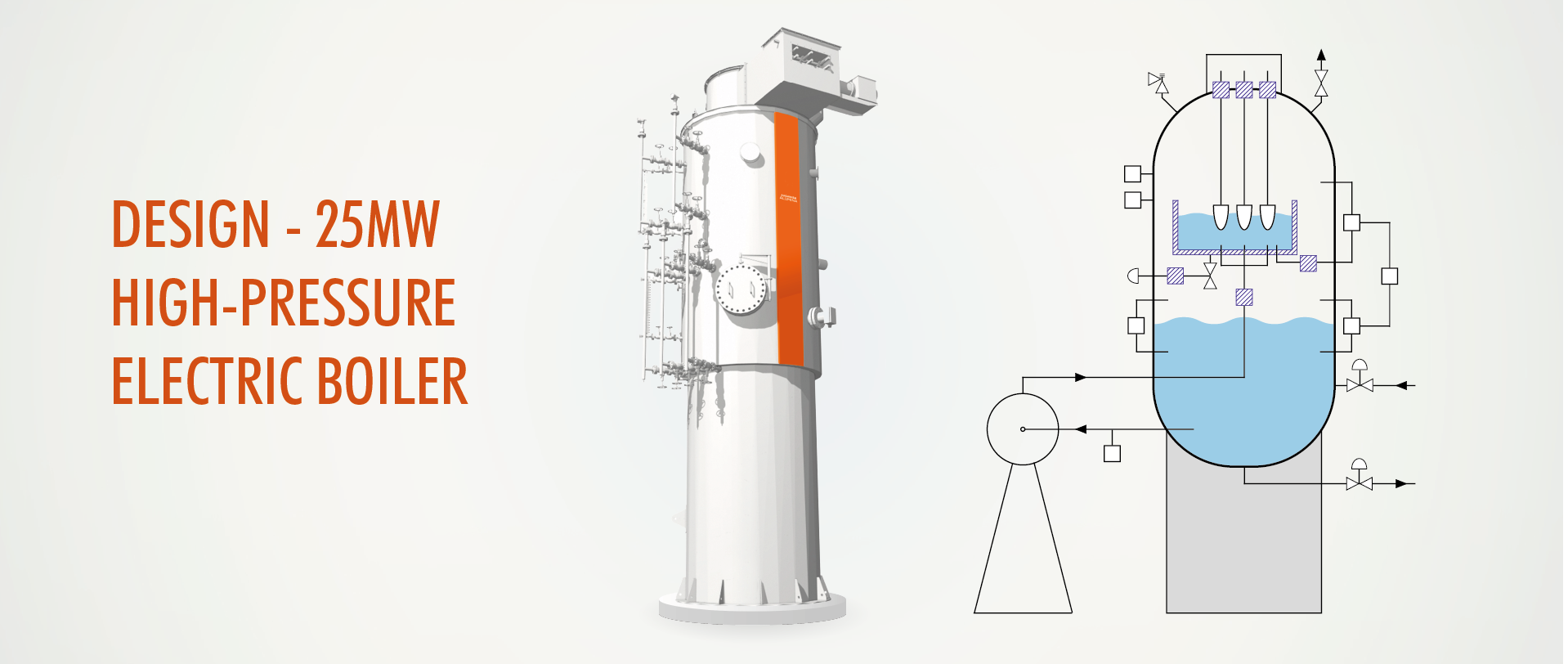

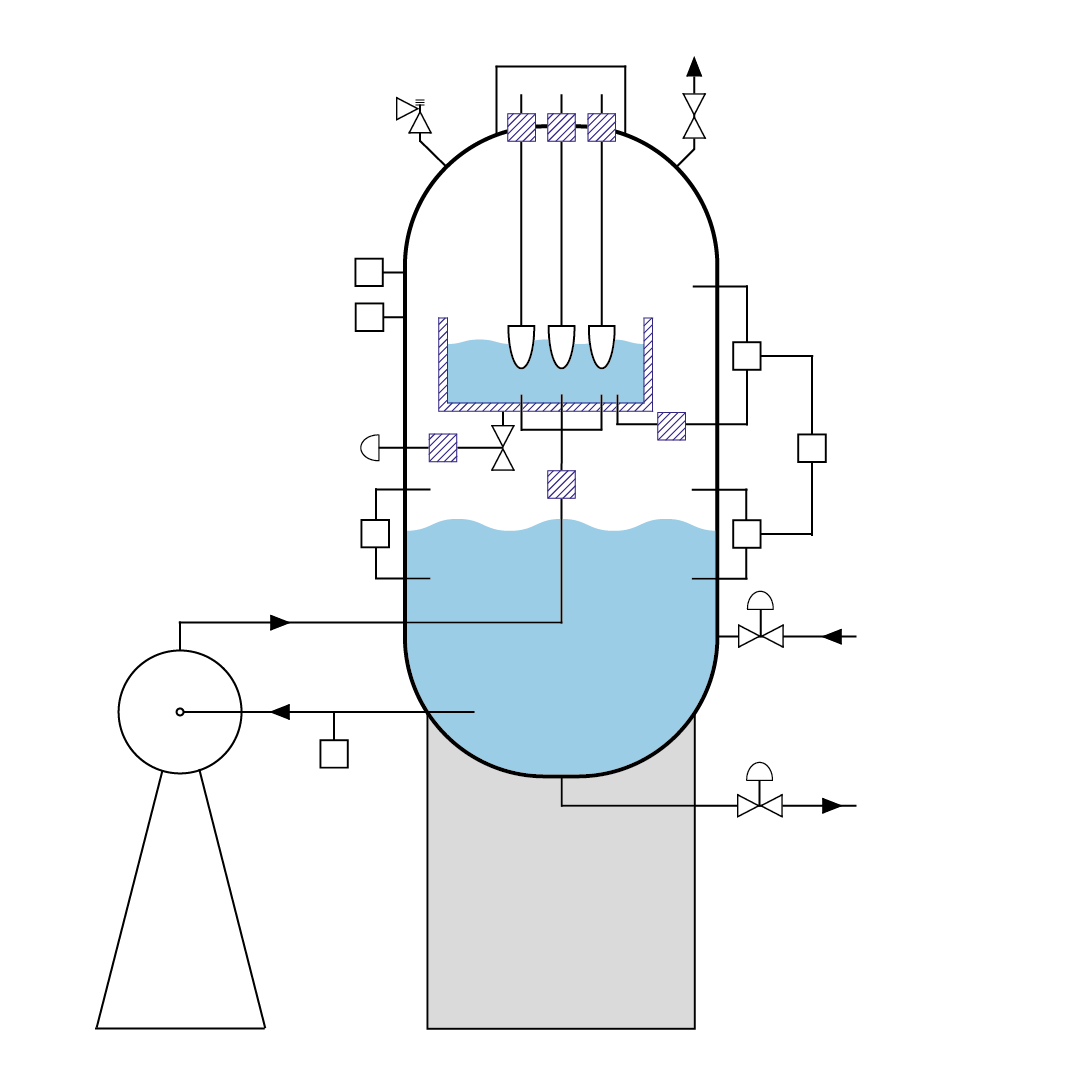

Unlike a conventional fired boiler no hot surfaces are required as the heat is generated directly in the water itself. Electric boilers of this type operating at up to circa 30 bar g have been in operation since the 1950s. The electric boiler at Aughinish will be fed by renewable electricity at 22kV.

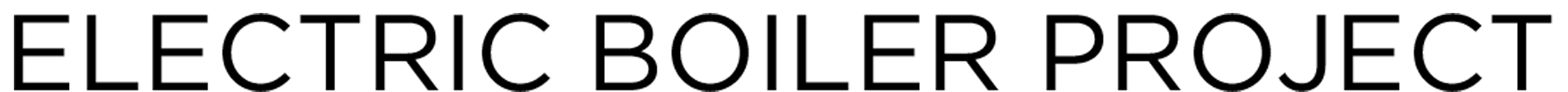

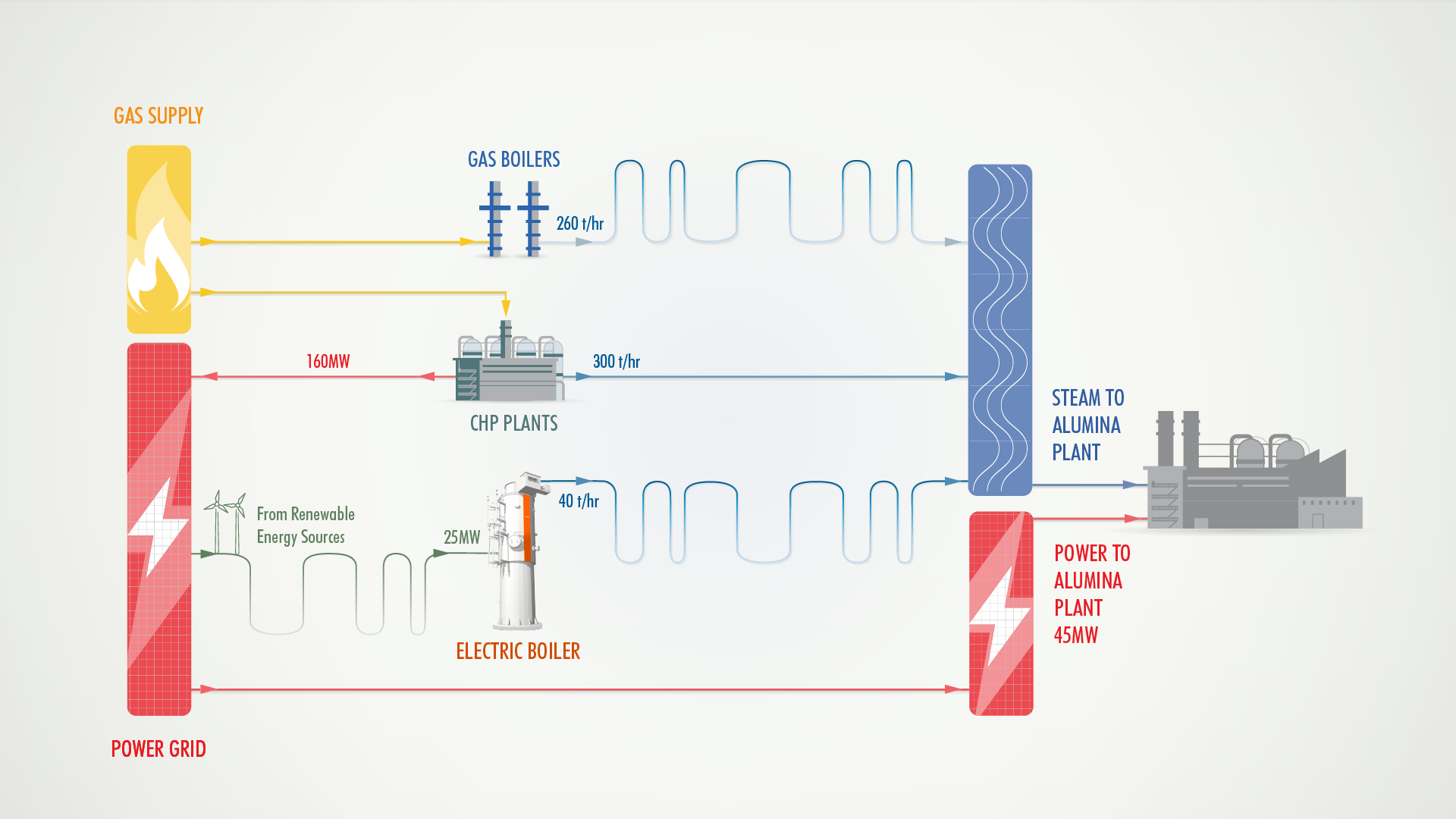

The nature of renewable energy supply is that it is variable and this is a major challenge for a plant that requires a constant fixed energy supply. The project will demonstrate the integration of the electric boiler with both the electrical power grid and the existing plant steam generating units: the Gas Boilers and the Combined Heat and Power Plant (CHP) units.

The electric boiler will operate in times of high levels of renewable energy on the grid and consume power that would otherwise not be used. The steam produced from the electric boiler is zero carbon.

The electric boiler consists of an outer and inner container. High-voltage electrodes are suspended inside the inner container, which is electrically insulated from the outer vessel. Alternating current flows between three electrodes using the water as the current path. The electrical resistance of the water creates heat in the water itself such that steam is generated. As the water is boiled off to generate steam the insulated inner chamber is continuously replenished with water from the outer vessel via the circulation pump. The output of the boiler is proportional to the water level of the electrodes.

Unlike a conventional fired boiler, no hot surfaces are required as the heat is generated directly in the water itself. Electric boilers of this type operating at up to circa 30 bar g have been in operation since the 1950s. The electric boiler at Aughinish will be fed by renewable electricity at 22kV. It is a 25MW boiler producing 40 tonnes per hour of high-pressure steam at 52.5 bar g and 330degrees Centigrade. An electrical superheater is fitted on the boiler outlet to increase the temperature of the saturated steam.

In a world first, initiated from Aughinish R&D, the design and the pioneering installation of a 25MW High-Pressure Electric Boiler will be the first application of this type within the alumina industry.

Low-pressure electric boilers operating at up to 30 bar g have been in operation since the 1950s, this first-of-its-kind boiler will produce steam at 52.5 bar g and is rated at up to 62 bar g.

This innovative high-pressure boiler has been developed between Parat and Equinor.

CONCEPT

Use excess renewable energy to produce steam for the alumina refinery and reduce use of natural gas

TECHNOLOGY

High-Pressure Electric Boiler converts excess renewable energy into steam with an efficiency of >99%

CO2 AVOIDANCE

20% utilisation of the Electric Boiler will reduce CO2 emissions by 10,000 tonnes annually

Dec 2021 - Aug 2022 - Engineering and Procurement

Sept 2022 - April 2023 - Delivery and Installation

Jul 2023 - Entry into Operation

2024 - Year 1 Green House Gas Verification

2026 - Year 3 Green House Gas Verification

2026 - Project Completion